Before discussing how an automatic transmission works, it’s important to discuss what it is. An automatic transmission is a type of transmission or manual transmission that can change gears automatically while the vehicle is moving. Manufacturers refer to it simply as an auto or AT (automatic variable speed transmission). It is also known as an “n-speed” automatic, where “n” is the number of forward gears.

This type of automotive transmission does not require the driver to change gears manually or by themselves. The driver controls the car using only the accelerator and brake. Let’s dive deeper to understand how an automatic transmission works.

Related: Top Car Brands in India

How does an automatic transmission work?

The most common form of automatic transmission in automobiles is hydraulic, although similar but larger units are used in heavy and industrial vehicles. Automatic transmissions use fluid clutches instead of friction clutches. It controls gear changes by hydraulically locking and unlocking the planetary gears.

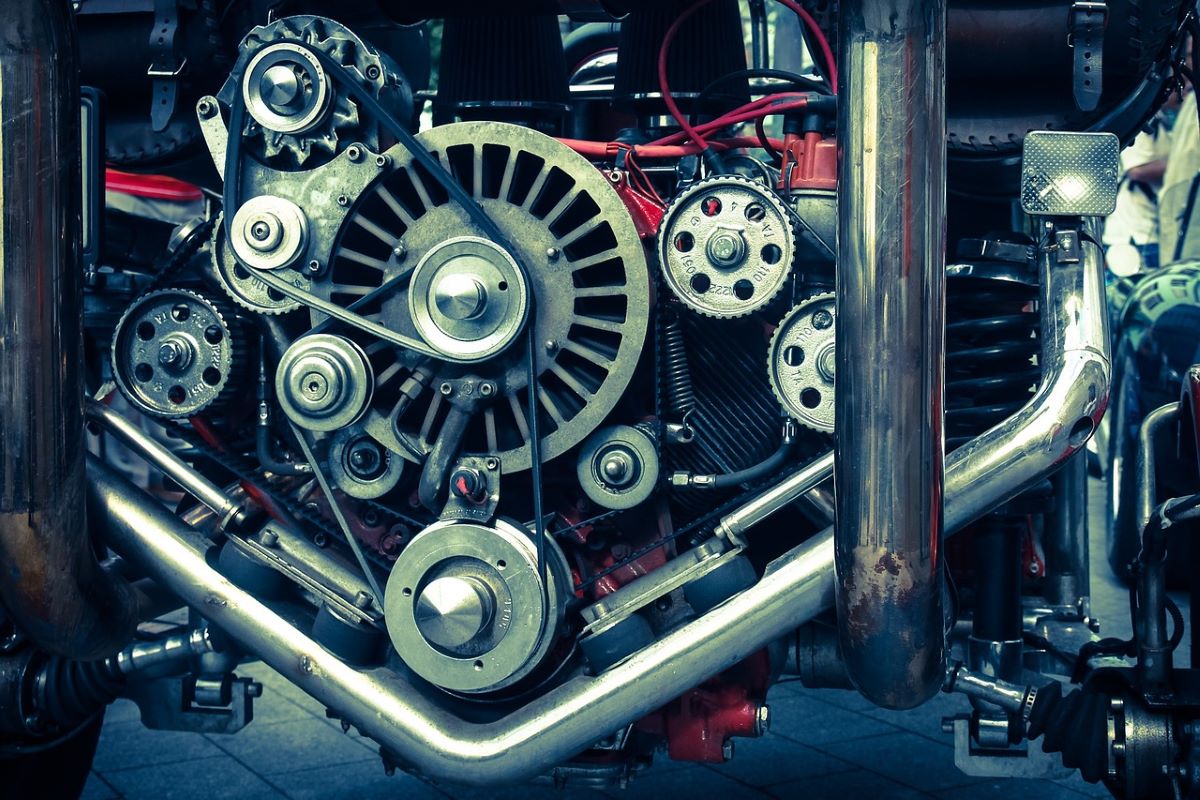

Automatic Transmission

Automatic transmissions have a specific number of gear ranges. They are often equipped with a parking brake which locks the transmission output shaft. This prevents the vehicle from rolling forward or backwards when parked. Some vehicles have a limited speed range or a stable engine speed, such as Forklifts and lawnmowers.

Such vehicles use only a torque converter to transmit the variable speed of the engine to the wheels.

Hydra-Matic Transmission

It is a fully automatic transmission. The Hydra-Matic drive combines a four-speed automatic forward and reverse transmission. Also, a fluid flywheel-like fluid clutch and torque converter are used for this purpose. The gearbox consists of three sets of helical planetary gears in series that are constantly meshing.

Two planetary gear sets provide four forward gears; the other set is reverse gear. A fluid flywheel dampens the effect of automatic gear changes and reduces the torque response of the engine.

Components of an Automatic Transmission System

The main types of automatic transmissions operate hydraulically. They use a fluid coupling or torque converter and a set of planetary gears to provide a variety of gear ratios. A hydrostatic automatic transmission consists of three main components: These include torque converters, planetary gears and hydraulic controls.

Torque Converter

It hydraulically connects and disconnects the engine and transmission. Torque converters also replace friction clutches in manual transmissions. It connects and disconnects the engine power from the planetary gears.

Additionally, it provides variable torque multiplication at low engine speeds, which improves start-off acceleration. Fluid couplings work well when both the impeller and turbine rotate at the same speed but become very inefficient during initial acceleration when their speeds are significantly different. Torque converters are constructed similarly to fluid couplings.

The torque on the transmission input shaft increases at low engine speeds. At a certain engine speed, it becomes inactive and therefore drops to the engine torque value. The torque converter consists of a driven impeller from the engine and a turbine attached to the transmission input shaft. There is also a small impeller called a stator between the impeller and the turbine.

How does a torque converter work?

It maximizes torque multiplication by having the stator vary the fluid flow depending on the relative speeds of the impeller and turbine. The stator itself does not rotate; however, manufacturers shape the blades so that when the impeller rotates faster, the turbine rotates slower.

The fluid flow strikes the turbine blades, multiplying the applied torque. This causes the turbine to spin faster as the vehicle accelerates. However, the torque increase diminishes as the relative speeds become equal. When there is a 10% difference between the impeller and turbine, the stator stops working and the torque converter acts as a simple fluid coupling.

Related: LED Headlights for New Dzire: First Look at Leaked Images

Planetary Gears

Planetary gears consist of multiple planetary gears. They also have clutches and bands to allow for different gear ratios. Depending on what the driver switches to the planetary gears, the speed of the output shaft changes. The transmission uses one of two types of clutches or bands to accomplish the gear changes and to hold certain elements of the planetary gear set stationary while allowing others to rotate.

This transfers torque and provides reduction or overdrive ratios. Valve bodies operate these clutches, and the automatic transmission’s standard program controls their sequence. Automatic transmissions mainly use roller clutches for routine up/downshifting. They work like a ratchet. They only transmit torque in one direction while coasting or overtaking.

The advantage of this type of clutch is that it eliminates the possibility of operating the clutch release simultaneously on two planetary gears. This means that it is under drivetrain load when actuated and automatically releases when the clutch of the next gear takes over torque transmission. The belt operates for the manually selected Low gear or reverse gear. It is active and acts on the circumference of the planetary drum.

When the drive/overdrive range of the transmission is selected, the band is not applied. Instead, the clutch transmits the torque. However, a tape may also be used for braking.

Clutch System

Each unit contains a multi-plate clutch for locking the gears in a direct drive. The front unit has two steel plates or discs that mesh with the sun gear drum to form the direct drive unit and also have three or more composite discs interleaved between the steel discs. These mesh with the hub of the planetary cage to form the driven part of the clutch.

The rear clutch is of similar construction, except that it contains more clutch plates. In turn, steel plates or discs are attached to an internally geared drum. The steel and composite discs interface with an intermediate shaft hub. The clutch plates are circular, just like the drum. When one of the clutches is operated, an annular piston presses the two sets of clutch plates into contact, which causes them to rotate together as a single locked unit.

The hydraulic pressure supplied by the control unit operates a piston, which acts as a pressure plate for the mechanical clutch. When the clutch is operated, it locks the sun gear and planetary cage of the front unit. However, the clutch locks the intermediate shaft hub and the internal gear drum of the rear unit.

Two passages through the transmission housing supply hydraulic pressure to the clutch, which operates an annular piston. They lead from the valve control unit to the oil supply sleeve.

Automatic Transmission System Manufacturer

BorgWarner, Cummins and ZF are the world’s leading manufacturers of automatic transmission systems.

Common Automatic Transmission Modes

- P – P stands for Park.

This selection allows the transmission output shaft to be mechanically locked. This prevents the vehicle from moving in any direction. However, the non-driven wheels of the vehicle can still turn freely. The differential effect can also cause the drive wheels to rotate independently.

Therefore, the handbrake (parking brake) which locks the wheels to prevent them from moving should always be used.

- R – R stands for reverse gear.

The reverse gear on an automatic transmission can be engaged to move the vehicle backwards. To initiate reverse on most transmissions, you must come to a complete stop, press the lock button, and then initiate reverse.

- N – N stands for neutral or no gear (N).

All gear trains in the transmission are switched off. It effectively isolates the transmission from the drive wheels, allowing the vehicle to turn freely under its weight and gain momentum.

Automatic Mode Forward Driving

- D – D stands for driving mode.

In this position, the automatic transmission has the full range of available forward gears available. Selecting a gear allows the vehicle to move forward and accelerate.

- [D] – [D] stands for Overdrive.

Some transmissions use this mode to perform automatic overdrive. In these transmissions, Drive (D) disables the automatic overdrive. The result is that OD (Overdrive) is engaged at constant speeds or low acceleration, around 56-72 km/h. However, if you accelerate hard or go below 35-45 mph (56-72 km/h), the transmission will automatically downshift.

- L/1 – L stands for low gear.

In this mode, the automatic transmission is locked in 1st gear only. Older vehicles are not capable of changing gears. Some vehicles will automatically upshift out of 1st gear in this mode to prevent engine damage when a certain RPM range is reached. There are other modes available depending on the make and model. D5 – Vehicles with a 5-speed automatic transmission often use this mode for highway driving. All 5 forward gears are used.

D4 – Vehicles with a 4- or 5-speed automatic transmission only use the first 4 gears.

This mode is primarily used in stop-and-go traffic. B. Used in urban traffic. D3 or 3 – 4-speed automatic cars only use the first three gears. However, it is mainly used in stop-and-go traffic.

B. Used in urban traffic. In D1, all three gears are used, but in D2, the car starts in 2nd gear and shifts up to 3rd. S or Sport S usually stands for Sport mode.

The functionality is the same as mode “D”, except that upshifts occur at a much higher engine speed. This maximises engine power and improves vehicle performance, especially during acceleration. This mode also downshifts at much higher RPMs than the “D” mode, maximising the effect of engine braking. However, this mode consumes less fuel.

Some newer vehicles also offer additional modes. For example: + − and M stands for manual gear selection in certain vehicles with automatic transmission. However, some models do not have the “M” – instead “+” and “-” are displayed. It is therefore different from the other switching modes. The driver can shift up and down freely by operating the gear lever as in a semi-automatic transmission.

The mode can be activated via the selector lever/position or by tilting the steering wheel paddle shifters to change gears. Winter (W) some models also have a winter mode. When starting from a stop, you are in second gear instead of first. This reduces the loss of traction caused by the wheel spinning on snow or ice.

Braking (B) B represents a braking mode offered by some models, including electric vehicles that allow you to slow down or maintain speed downhill without using the car’s brakes. For non-hybrid vehicles, B mode selects a lower gear to increase the effect of engine braking. In electric mode B, increased brake energy recuperation is achieved when the accelerator pedal is released.

Read Also: