If you’ve ever driven an automatic transmission car, you know two big differences between automatic and manual transmissions: Automatic transmission cars do not have a clutch pedal. Automatic cars do not have a shift lever. But, how does automatic gearbox work? As soon as everything else happens automatically when the car is in gear, everything transmissions (with a torque converter) and manual transmissions (with a clutch) both accomplish the same thing but in very different ways.

The way automatic transmissions accomplish this is downright amazing. In this article, we’ll discuss automatic transmissions. In this article, we will cover everything about how does automatic gearbox work.

Related: Traffic Signal Rules You Must Know About

How Does Automatic Gearbox Work?

We start with the planetary gears, which are the key to the entire system. We then look at how the transmission is assembled, learn about the controls, and discuss the finer points of transmission control. Like a manual transmission, the main role of an automatic transmission is to keep the engine operating within a narrow speed range while providing a wide range of output speeds.

Without a transmission, the car would be limited to one gear, which must be selected for the car to reach its desired top speed. If you want to reach a top speed of 80 miles per hour, most manual cars have a third-gear ratio. You’ve probably never driven a manual car with only three speeds.

If you do, you’ve quickly noticed that it has almost no acceleration when starting and the engine revs close to the redline at higher speeds. Such cars would quickly wear out and become almost undrivable. Thus, the transmission uses gears to more effectively use the engine torque to keep the engine revving at the right speed.

When towing or transporting heavy loads, your vehicle’s transmission can get so hot that the transmission fluid can burn. To protect the transmission from serious damage, drivers who tow trailers should purchase vehicles with transmission coolers.

The main difference between a manual transmission and an automatic transmission is that in a manual transmission, different sets of gears are locked and unlocked on the output shaft to achieve the different gear ratios, while in an automatic transmission, the same set of gears produces all the different gear ratios.

The device that makes this possible in an automatic transmission is the planetary gears. Let’s take a look at how planetary gears work.

Planetary Gears From left to right

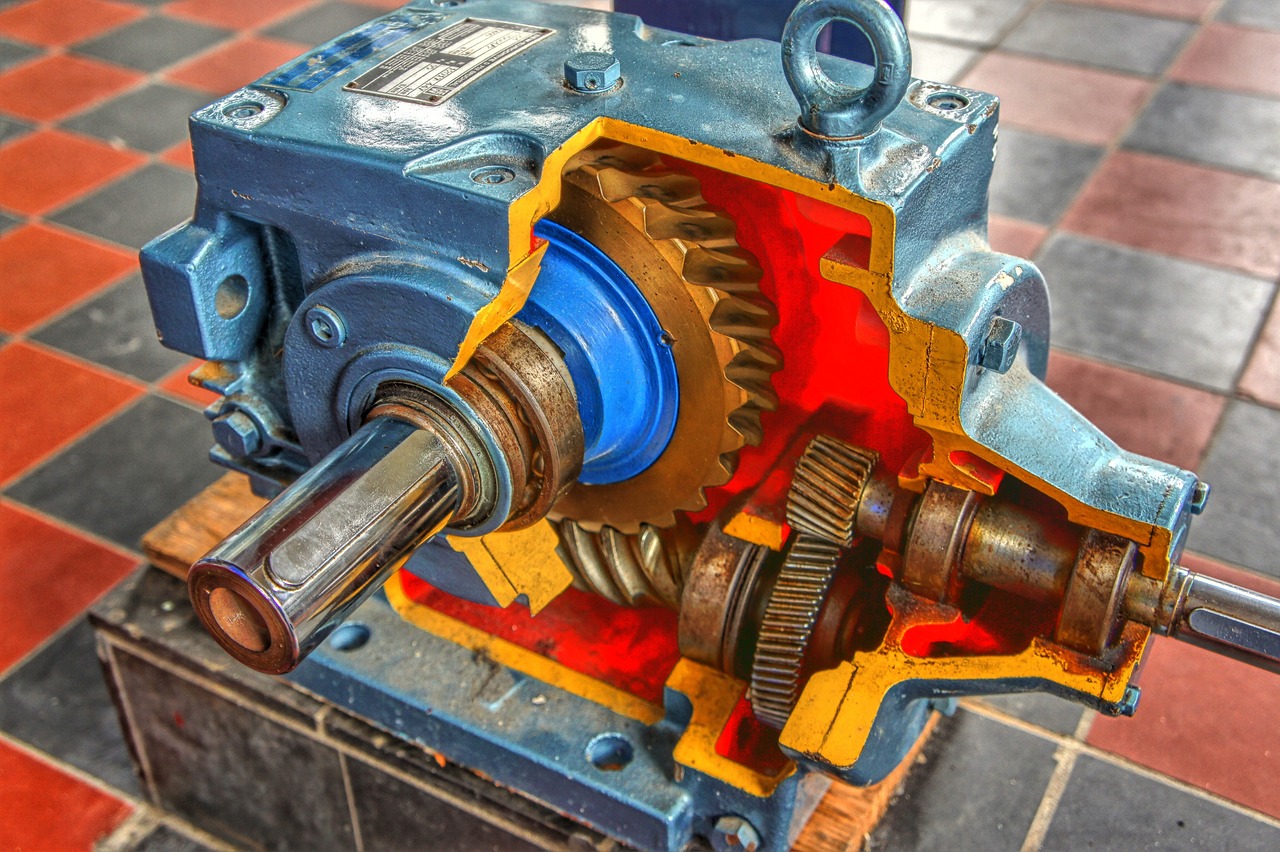

When you disassemble an automatic transmission, you’ll see a huge number of parts packed into a relatively small space. Other things you can see include:

- A sophisticated planetary gear

- A set of bands to lock parts of the transmission

- A set of three wet disc clutches to lock other parts of the transmission

- An incredibly strange hydraulic system and bands that control the clutches

- A large gear pump for the moving gear oil

Each planetary gear consists of three main components:

- Sun gear Planet gears and planet carrier

- Ring gear

Each of these three components can be input, output or fixed. Choosing which part plays which role determines the gear ratio of your transmission.

Planetary Gear Gear Ratios

A variety of gear ratios can be obtained from this gearbox. Locking any two of the three components together locks the entire device with a gear ratio of 1: 1. Note that the 1st gear ratio above is a reduction ratio; the output speed is lower than the input speed.

The second is an overdrive; the output speed is higher than the input speed. The last is a reduction as well but in the opposite direction to the first. Several other gear ratios can be derived from this planetary gear set, but these are the ones that are relevant to our automatic transmission.

So with this one set of gears, we can create all of these different gear ratios without having to connect or disconnect any other gears. Putting two of these gear sets back to back gives us the four forward gears and one reverse gear we need for the transmission. In the next section, we’ll look at the two gear sets together.

Compound Planetary Gears

This automatic transmission uses a set of gears called compound planetary gears that look like a single planetary gear but behave like two planetary gears combined. There is one ring gear that is always the output of the gearbox, but there are two sun gears and two planetary gear sets.

1st Gear

In 1st gear, the smaller sun gear is driven clockwise by the turbine in the torque converter.

The planet carrier tries to rotate counterclockwise but is held in place by the one-way clutch (which only allows clockwise), and the ring gear rotates the output. The small gear has 30 teeth and the ring gear has 72 teeth, so the gear ratio is: Ratio = -R/S = – 72/30 = -2.4: 1. So the rotation is negative 2.4: 1. This means that the output direction is opposite to the input direction.

However, the output direction is the same as the input direction. This is where the two planetary set tricks come into play: the 1st planet gear meshes with the 2nd gear, which rotates the ring gear. This combination reverses the direction. This means that the larger sun gear also rotates.

But because the clutch is released, the larger sun gear is free to rotate in the opposite direction to the turbine (counterclockwise).

Second Gear

This gearbox has a very clever feature to achieve the required gear ratio for the second gear. It behaves like two planet gears connected through a common planet carrier. The first stage of the planet carrier uses the larger sun gear as a ring gear. The first stage consists of the sun gear (smaller sun gear), the planet carrier and the ring gear (larger sun gear).

1 + R/S = 1 + 36/30 = 2.

2: 1 the planet carrier rotates 2.

2 times for each revolution of the small sun gear.

In the second stage, the planet carrier acts as the input to the second planetary gear set, the larger sun gear (which is fixed) acts as the sun, and the ring gear acts as the output, giving a gear ratio of 1. / (1 + S/R) = 1 / (1 + 36/72) = 0.67: 1

To get the total gear ratio for the second gear, multiply the first stage by the second stage:

2.2 x 0.67.

This gives a gear ratio of 1.47:1.

THIRD GEAR

Most automatic transmissions have a third gear ratio of 1: 1. As you’ll remember from the previous section, to get a power output of 1: 1, you only need to add any two of the three components. The planetary gears must be interconnected. With this gear set arrangement, the job is even easier, as you only need to connect the clutches that connect each sun gear to the turbine.

When both sun gears rotate in the same direction, the planet gears are locked as they can only rotate in the opposite direction. This connects the ring gear to the planet so they all rotate as one unit, forming a 1: 1 ratio.

Overdrive

By definition, an overdrive has an output speed that is faster than the input speed. This is an increase in speed, the opposite of a decrease in speed. In this transmission, engaging overdrive does two things at once: If you’ve read “How a Torque Converter Works,” you learned about a lock-up torque converter.

For greater efficiency, some vehicles have a mechanism that bypasses the torque converter and sends engine power directly to the transmission.

The small sun gear spins freely and the large sun gear is held in place by the overdrive band. Nothing is connected to the turbine. The only input is from the converter housing.

Reverse Gear

Reverse gear is very similar to 1st gear, except here we have a small sun gear that freewheels in the opposite direction to the larger sun gear, rather than a small sun gear driven by the torque converter turbine. The planetary carrier is held in the housing by a reverse band. According to the equation on the last page: So in this transmission, the gear ratio of reverse gear is slightly lower than the gear ratio of 1st gear.

Clutches and Bands in an Automatic Transmission

In the previous section, we discussed how the individual gear ratios are produced by the transmission. For example, when we talked about overdrive we said: When this transmission is in overdrive, the shaft attached to the torque converter housing (which is bolted to the engine’s flywheel) is engaged by a clutch connected to the planet carrier.

The small sun gear spins freely and the large sun gear is held in place by an overdrive band. Nothing is connected to the turbine. The only input is from the converter housing. To put a transmission into overdrive various things must be connected and disconnected by clutches and bands. The planet carrier is connected to the torque converter housing by a coupling.

The small sun gear is disconnected from the turbine by a clutch and is allowed to spin freely. The large sun gear is secured to the housing by a band to keep it from rotating. Every time you change gear it triggers a chain of events that engages and disengages various clutches and belts.

Bands

This gear has two bands. The gearbox bands are steel bands that wrap around the gearbox parts and connect to the housing. These are operated by hydraulic cylinders in the gearbox housing. The clutches in the transmission are a little more complicated. There are four clutches in this transmission.

Each clutch is actuated by hydraulic fluid under pressure entering a piston inside the clutch. When the pressure is released, a spring ensures that the clutch is released.

When parking the car locking the transmission to prevent it from spinning seems simple, but in reality, the mechanism has several complex requirements. First, it must be able to disengage when the car is on a hill (when the weight of the car is bearing down on the mechanism). Second, the mechanism must be able to engage even when the lever is not aligned with the gear.

Third, something needs to prevent the lever from jumping up and releasing the clutch after it is engaged. When you put the shifter in park, the rod presses a spring against a small tapered bushing. When the parking mechanism is oriented so that it drops into one of the notches in the output gear section, the tapered bushing presses down on the parking mechanism.

When the mechanism is aligned with one of the high output points, the spring presses against the tapered bushing, but the lever doesn’t engage until the car has been rotated slightly so that the teeth are properly aligned.

This is why your car may move a little after you put it in the park and release the brake pedal. You need to rotate the car slightly to align the teeth and put the parking mechanism into position.

Read Also: